MoVeHo

Model-based in-process tool wear determination in high-performance turning

Tools are of central importance for productivity and manufacturing costs in metal-cutting production. The maximization of tool life is therefore the focus of tool development, especially in high-performance machining. Here, the main focus is on the use of hard coatings and coating systems to optimize the property profile of the tools. Despite the variety of tool coatings used, there are still considerable deficits in the understanding of the underlying wear mechanisms. To reduce these deficits, a novel greybox model is developed for the process of high-performance turning. The model combines complementary methods for tool wear determination (knowledge- and data-based models) and uses data sources from in-process measurements for the wear investigation that have not been considered so far.

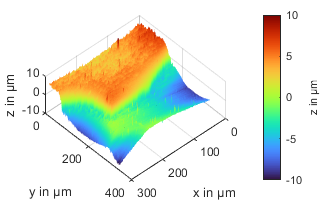

For the training of the data-based neural network, the wear parameters of the cutting tool in the workspace of a machining process must be determined. This requires in-situ measurement methods for the tool geometry and layer thickness. In the project MoVeHo, optical measurement methods are studied, which do not affect the cutting process, allow good accessibility without spatial restriction of the process and offer high spatial and temporal resolutions.

A previous study showed that photothermal radiometry is suitable for quantitative thickness measurements of the nitride layer under in-process conditions in an industrial nitriding furnace. In MoVeHo, the signal model will be enhanced from single-layer to multi-layer systems. In addition, a laser line triangulation sensor is used to measure the tool geometry. Both sensor systems will then be mounted on a 6-axis industrial robot in the turning machine, to collect an extensive data basis during numerous tool wear experiments for the training of the blackbox model component as part of the greybox model.

| Runtime: | 01.02.2024-31.01.2027 |

| Funding authority: | DFG - German Research Foundation |

| Funding programme: | Schwerpunktprogramm |

| Funding ID: | FI 1989/17-1 |

| Partner: |